direct drive motor vs belt

The key difference is how the motor drives the record platter. With a belt drive fan the size of the sheaves can be adjusted to provide a wide range of slower propeller speeds while utilizing the cheapest motor a.

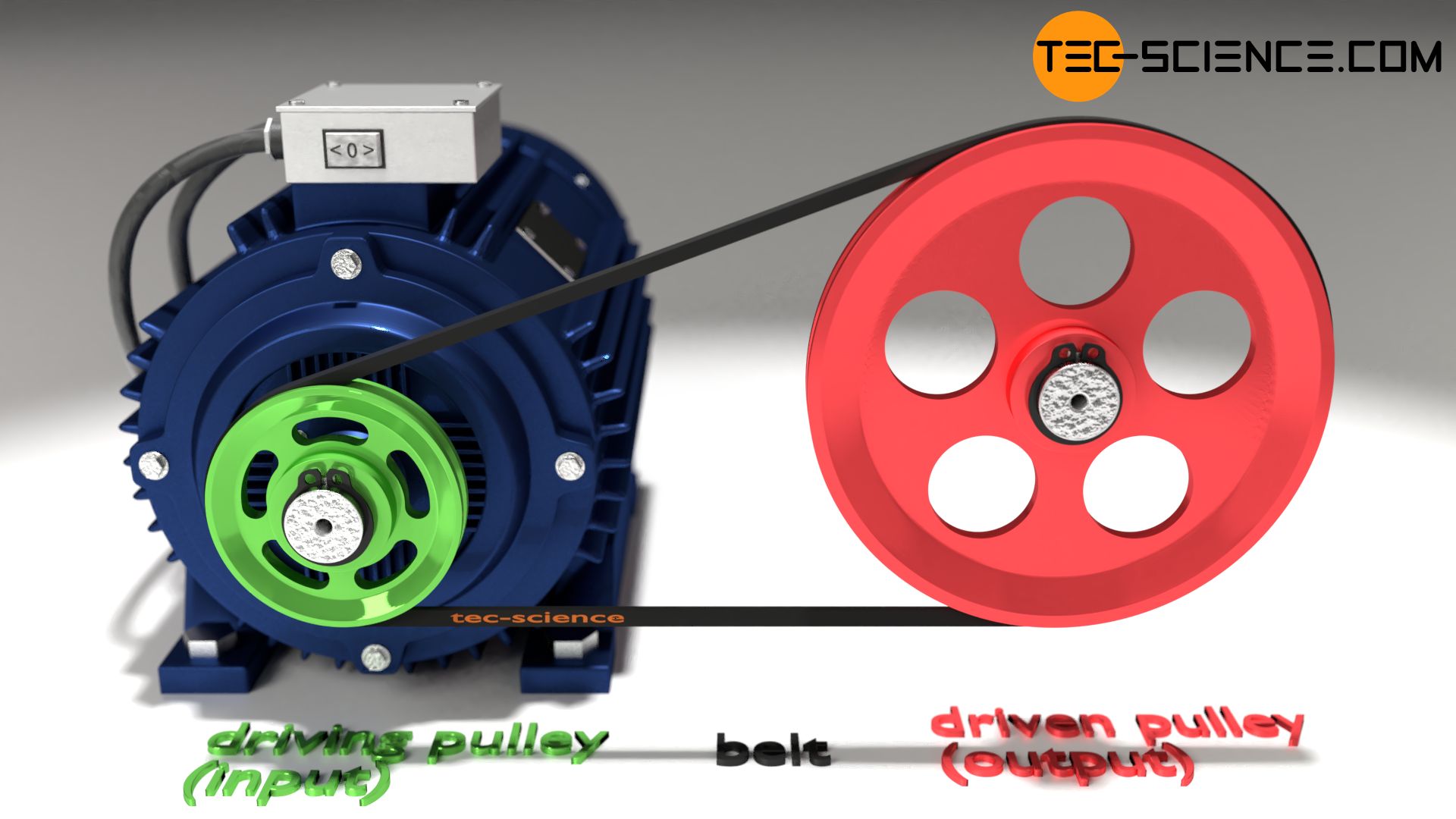

How Does A Belt Drive Work Tec Science

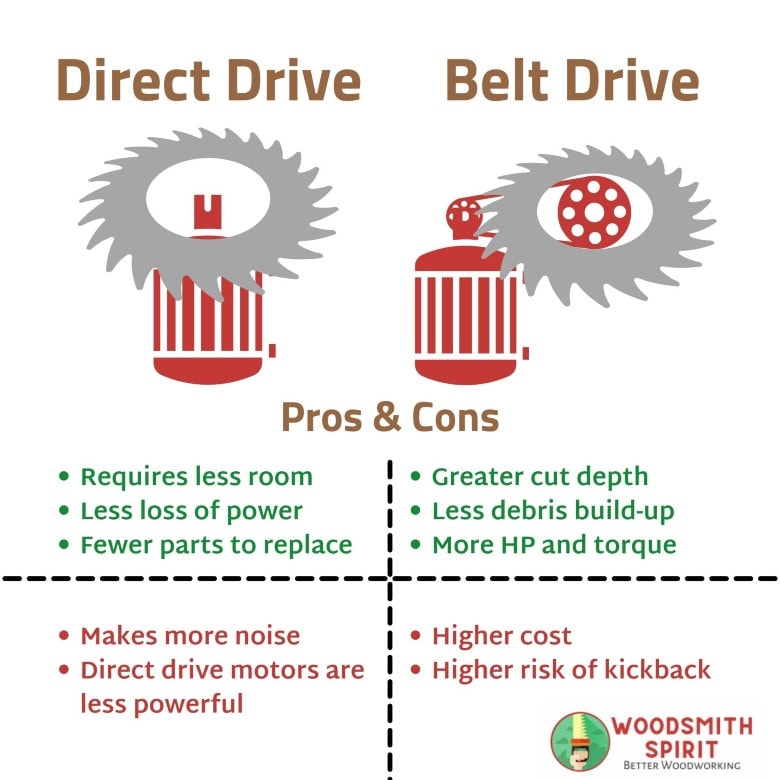

Belt drives apply greater load on the main shaft of the machine it has a direct effect on the life time of bearings shaft misalignment and as a result oil leakage and more vibrations.

. A belt-driven turntable uses a belt to move the platter. Direct drive washing machines are 28 more energy efficient when compared to belt drive washing machines. In addition when you turn off the direct-drive turntable the platter rotates without resistance hence minimizing the chance of damage.

Direct drive in the true sense means that the motor is directly connected with the rotor Coaxial which has the same speed. When it comes to belt vs. Check out my gear on Kit.

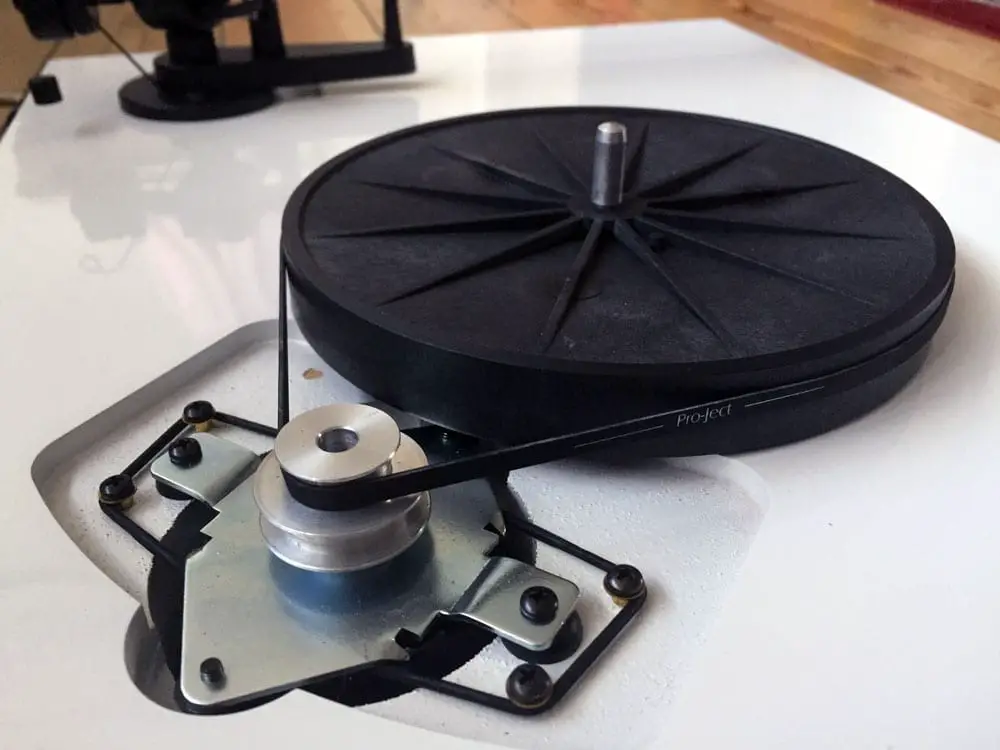

The direct drive is mainly created for the DJs and designed to work with two turntables while the belt drive doesnt possess such functions. While torque isnt necessarily a critical quality it can be a deal-breaker for some. A belt-drive has a platter that sits on a bearing and is driven by a pulley-style belt usually made of rubber.

Because of this there is far less wear and tear when compared to belt drive motors. Direct drive washing machines do not have any moving parts in the motor. The motor that drives the belt is positioned off to the side.

Belt drive motor table saws are not very portable. A direct drive system usually uses brushless motors that do not make more noise. This situation is obviously very rare.

Assuming speed reduction a direct drive low speed motor will have a lower efficiency lower power factor bigger size and higher cost as compared to belt driven higher speed motor. Of course belts themselves have plus. Direct driven motors also have a smaller footprint which means they can be placed in more places due to their small size.

They both are different in how the motor spins and their design differs from each other. Over time a belt drive may need to be replaced. You will have less chance of motor noise getting picked up by your stylus and the speed should be perceived as more pure.

Belt Drive motors are used to transmit power over much larger distances with considerable reduction in power. The belt also requires proper maintenance and wear and tear is much more in belt drive than in Direct Drive Motors. Thus I have emphasized two features.

On direct-drive turntables the motor is located directly under the support platter. This improves the pumps ability to draw water and detergent from a standing source it has greater suction capability. We feel that if you can get those two right then in almost all cases the belt drive will outperform the direct drive for sheer musical enjoyment.

The belt driven system. Therefore it is a wrong view that there is no energy loss in direct drive. While belt drive turntables are incredibly popular they have a lower torque than direct drive turntables.

In the case of direct-drive designs the platter sits directly on the motor. A direct-drive automatic turntable has a motor located directly under the platter and it rotates using the bearing. Direct-drive turntable remember this is not the same as a belt-drive turntable with a motor connected to the platter with a belt.

Another drive way is belt driven which allows the rotating speed of the rotor to be changed by pulleys of different diameters. The propeller speed of a direct dive fan is limited to the standard motor speeds. They can also spin faster without overloading the motor.

See also What to do if your house has no sewer cleanout Using a pulley system the motor transfers power through the belt to. We discuss positives and negatives for eac. The second most distinct difference between the two is price.

Direct-drive motors are generally heavier than belt-driven motors so they offer higher torque and power at slower rpms. In summary price and the fact that belt drive motors are not attached directly to the turntable are the two biggest differences. Direct Drive Motors are generally used in washing machines and is much than belt rive motors.

If you look at Energy Star ratings youll see that nearly all of the energy-efficient top-ranked models are direct-drive versions. Belt drive pumps are therefore subject to less wear and tear than direct drive pumps and have a longer lifespan. With their extreme longevity direct-drive motors go longer without a repair.

Heres a helpful overview explaining the differences between a belt-drive motor and a direct-drive fan motor. The motor function of the direct drive is different from the belt drive. Direct drive turntables usually pick up speed almost instantly and have a steady speed.

The direct drive system eliminates the belt from the drive system. Unlike belt driven fans theres. The motor is directly mounted underneath the washing machine drum.

Direct drives requires less space in comparison to belt drives so smaller machines. They are much heavier than direct drive saws and they require a lot more space in your workroom. Both are created for different audiences.

Which design is best. However broken parts will require a technician with training which can be challenging to find. As you might have guessed the primary difference between a direct drive motor and a belt drive motor is that the former does not utilize a belt.

A direct-drive turntable on the other hand will skip the belt bit and feature a platter connected to the motor directly through the spindle at the heart of the plate. Begingroup Variable frequency drive and belt drive are not an either-or proposition. Belt Drive Motor Vs.

Machined steel pulleys and a link belt will lessen vibration. No more power loss as the motor shaft is directly connected to the drum shaft. Belt drive pumps allow for a longer stroke and increased stroke time due to the reduced RPM.

The spinning speed of direct drive washers is 8 more efficient than the belt drive washers. Belt drive turntables also have a slightly less accurate playback speed than direct drive turntables.

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Types Of Belt Drive Material Applications Advantages Disadvantages Engineering Learn

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

The System Benefits Of Direct Drive The Comparison Tab Tv

Belt Drive Vs Direct Drive Laundry Youtube

Difference Between Direct Drive And Belt Drive Washing Machine Youtube

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Table Saw Motor Drive Types And Specs Explained Guide

Direct Drive Vs Belt Drive Washing Machines Which Is Better Survival Freedom

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

What S The Difference Between A Hub Drive And A Belt Drive Electric Sk Electric Board Co

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Direct Drive Vs Belt Drive Washing Machines Which Is Better Survival Freedom

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Drive Turntables What S The Difference Sound Matters